Product Standard : BS EN 12201-3 : 2011

The PE Socket Fusion Fitting is the most cost-effective fusion system that produces homogeneous material joints of pipes & fittings by heat welding method. Fusion joints are most reliable joints that provide better assurance and leak-free performance. They are applicable for materials like PE, PPR, PERT and PB.

The socket fusion joining method has become common and widely used especially for larger pipe diameters. We capitalize on this trend and introduce the most cost effective PE materials. We “refine” the jointing method including the invention of "smart-RINGTM" to perfect the overall system performance.

smart-RINGTM (SR-1)

The proprietary invention of smart-RINGTM (SR-1) enables the socket fusion jointing process to be more consistent, easier and faster with following superior features :

- As a guide to verify pipes OD specifications

- Width of ring indicates insertion depth

- Threading created on pipes help to peel off oxidized surface layer

- Improve roundness of pipes for socket fusion process

- Guide to assure 90˚ alignment of pipes & fittings perpendicularity

- Cover excessive beads after welding and allow inspection of beads

- 4-alignment lines to prevent twisting of pipes during installation

- Helpful processing information on rings to assist correct installation

- Reinforce the bending strength at joints

- Assure neat & tidy installation

| OD, mm | Insertion Depth, mm | Heat Time, s | Hold Time,s |

|---|---|---|---|

| 20 | 11 | 8 | 6 |

| 25 | 13 | 9 | 10 |

| 32 | 15 | 11 | 10 |

| 40 | 17 | 16 | 20 |

| 50 | 20 | 24 | 20 |

| 63 | 24 | 33 | 30 |

| 75 | 26 | 43 | 30 |

| 90 | 28 | 55 | 40 |

| 110 | 33 | 70 | 50 |

Heating temperature 260°c

Installation Procedures

| 01 | 02 | 03 | 04 |

|

|

|

INSERT the pipe into the fitting (inspect full insertion thru windows) |

PRESS the stainless steel sleeve with the pressing tool (pressed lines are formed) |

Product List

| Equal Socket | Reducing Socket | Male Socket | Female Socket |

|

|

|

|

|

| Equal Elbow | 45˚ Elbow | Male Elbow | Female Elbow |

|

|

|

|

|

| Flange Adapter (Stub End) | |||

|

|

|

|

|

| Male Tee | Female Tee | End Cap | Stop Valve |

|

|

|

|

|

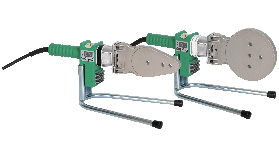

| Roller Cutter | Socket Welder (Set) | Heating Bushes | Bench Welder (Set) |

|

|

|

|

|