ASTM F1282 : 2010 (PE-AL-PE) & AS 4176-2 : 2010 (PEX-AL-PEX) & AS 2492 : 2007 (PEX)

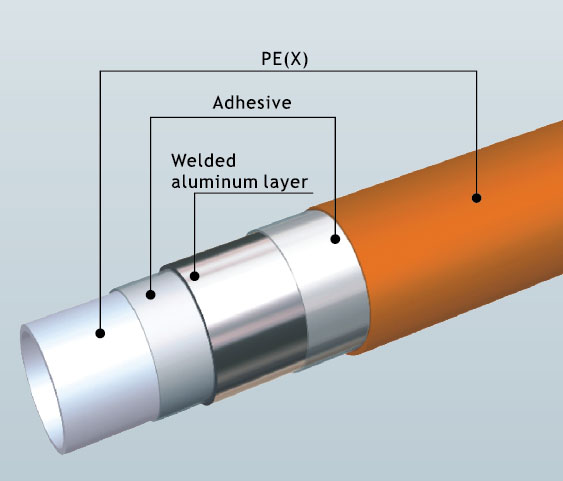

Composite Polyethylene Aluminium (PA) pipe, in the form of PE-AL-PE or PEX-AL-PEX, is the composite pipe of 5 layers. It consists of a middle Aluminium layer with an inner and outer plastic layers, tightly bonded with a special adhesive to the Aluminium core. The plastic materials used for the inner and outer layers are either cross-linked polyethylene (PEX) or polyethylene (PE), which is hygienic, toxic-free and smooth. The middle Aluminium layer is absolutely 100% diffusion tight which reliably prevents gases and oxygen from permeating into pipe. Such structure compensates and reduces snap-back forces and heat expansion with changes of temperatures. The composite PA pipe combines the advantages of both metal and plastic while avoiding both of their weaknesses.

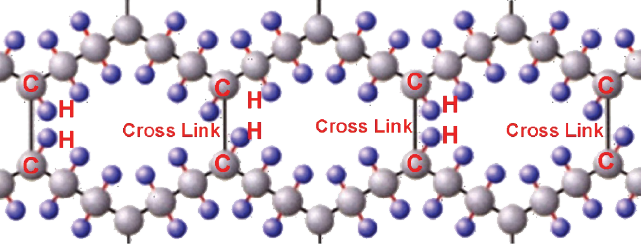

PEX Material

PEX (Cross-linked Polyethylene) is a high performance and flexible polymer pipe. It is formed by chemically bonding individual polyethylene molecules in order to enhance the physical properties and to improve the performance of the original base resin in higher temperature and pressure conditions.

Smooth Surface for Higher Flow Rate

Base on “Hazen-Williams” equation, PEX pipes have smoother surface (low roughness coefficient), hence able to increase the flow rate. And in terms of dimensional calculation, use of relatively smaller pipe inner diameter can be considered yet achieving equivalent flow rate.

Specifications

| Nominal (mm) | 16 | 20 | 25 | 32 | 40 | 50 | 63 |

| Inner diameter (mm) | 12 | 16 | 20 | 26 | 32 | 41 | 51 |

| Wall thickness (mm) | 2.0 | 2.0 | 2.5 | 3.0 | 4.0 | 4.5 | 6.0 |

| Aluminium thickness (mm) | 0.20 | 0.24 | 0.30 | 0.70 | 0.70 | 0.70 | 0.70 |

| Pipe weight (kg/m) | 0.125 | 0.170 | 0.252 | 0.390 | 0.600 | 0.860 | 1.320 |

| Internal volume of water (l/m) | 0.113 | 0.201 | 0.314 | 0.531 | 0.960 | 1.385 | 2.289 |

| Working temperature (°C) PE-AL-PEX pipe |

A range of - 45°C to 60°C 60°C at 4 Bars / 20°C at 12.5 Bars |

||||||

| Working temperature (°C) PEX-AL-PEX pipe |

A range of - 45°C to 95°C Peak temperature : 110°C (max duration of 1 hour) |

||||||

| Max working pressure (Bars) | 95°C at 4 Bars / 70°C at 10 Bars | ||||||

| Burst pressure (Bars) | 80 | ||||||

| Min ring strength (N) | ≤ 2,000 | ≤ 2,400 | ≤ 2,400 | ≤ 2,650 | ≤ 3,200 | ≤ 3,500 | ≤ 5,200 |

| Thermal conductivity (W/mK) | 0.43 (vs copper at 28.0) | ||||||

| Coefficient of thermal expansion (mm/m*K) | 0.025 - 0.030 | ||||||

| Surface roughness of inner pipe | 0.007mm (7um) | ||||||

| Oxygen barrier (%) | 100 | ||||||

| Bending radius (free bend) | ≥ 6x of pipe outer diameter | ||||||

| Bending radius (with tool) | ≥ 3.5x of pipe outer diameter | ||||||

| Working life-span | > 50 years | ||||||

| Length in coil (m) | 100 | 100 | 100 | 50 | 50 | 50 | 50 |

| Length in straight tube (m) | - | - | - | - | 5 | 5 | 5 |

| Equivalent to copper pipe sizes (mm) | 15 | 18 | 22 | 28 | 35 | 42 | 54 |

| Equivalent to stainless steel pipe sizes (inch) | 3/8" | 1/2" | 3/4" | 1" | 1 1/4" | 1 1/2" | 2" |

| Equivalent to PPR (PN20) pipe sizes (mm) | 20 | 25 | 32 | 40 | 50 | 63 | 75 |

Main Applications